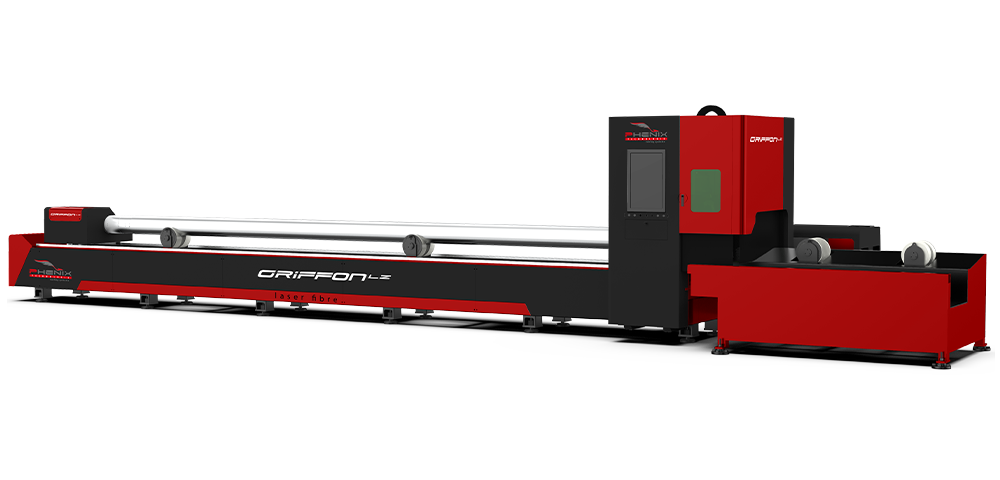

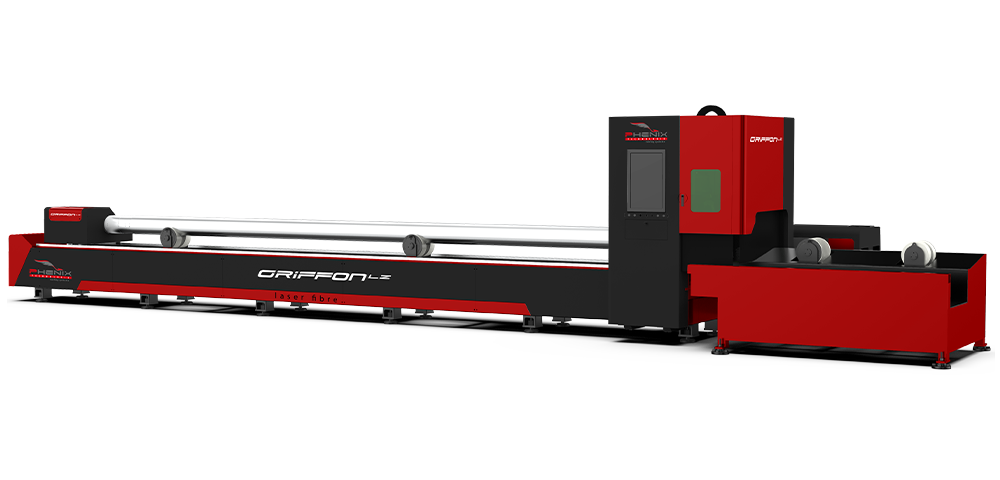

GRIFFON LZ is a specific fiber laser tube cutting machine designed for precise metal part cutting, automotive industry components, plumbing tubes, construction structures, and many other applications where precise and rapid cutting is required. GRIFFON LZ delivers high precision, great flexibility, high efficiency, and a finish with precise tolerances. The heat generated by the laser melts or vaporizes the material at that precise location, allowing for precise and clean cutting or engraving of the material. The laser is directed using a fiber system of mirrors or lenses to follow a specific pattern or trajectory. GRIFFON LZ offers a high degree of precision, great flexibility, high efficiency, and a finish with precise tolerances, meeting the requirements of the intended application. It is particularly suitable for cutting materials such as mild steel, stainless steel, aluminum, and brass. GRIFFON LZ enables cutting of conventional tubes, including round, square, and rectangular tubes, as well as profiles such as U-shaped steels, angles, and H-profiles. Additionally, it facilitates easy cutting of tubes with special shapes, including triangular tubes, concave tubes, and other specific configurations. This system can operate independently or be networked.

| L160 | L220 | H230 | H345 | |

|---|---|---|---|---|

WORK AREA | 6300 mm | 6300 mm | 6300 mm | 6300 mm |

MAXIMUM LINK SPEED | 140m/min | 140m/min | 140m/min | 140m/min |

MAXIMUM ACCELERATION | 1,5G | 1,5G | 1,5G | 1,5G |

POSITIONING ACCURACY | ±0,03mm | ±0,03mm | ±0,03mm | ±0,03mm |

PIPE SECTION SHAPE | Rond, carré, rectangulaire | Rond, carré, rectangulaire | Rond, carré, rectangulaire | Rond, carré, rectangulaire |

RANGE OF TUBE SIZES | rond : Φ16-Φ155mm carré : □16-□155mm rectangulaire : Coté long ≤ 155mm | rond : Φ20-Φ220mm carré : □20-□220mm rectangulaire : Coté long ≤ 220mm | rond : Φ20-Φ220mm carré : □20-□220mm rectangulaire :Φ≤ 220mm | rond : Φ20-Φ345mm carré : □20-□240mm rectangulaire : Φ≤ 345mm |

MAXIMUM PIPE LENGTH | 6.3m | 6.3m | 6.5m/9.2m | 6.5m/9.2m |

MAXIMUM PIPE WEIGHT | 100Kg 16Kg/m | 200Kg 30Kg/m | 200Kg 30Kg/m | 500Kg 83Kg/m |

MAXIMUM DELETION LENGTH | 2m | 2m | 2m | 2m |

REMAINS THE SHORTEST | 150mm | 150mm | 200mm | 200mm |

POSITIONING ACCURACY | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

REPOSITIONING ACCURACY | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

MAXIMUM CHUCK SPEED | 80r/min | 80r/min | 120r/min | 120r/min |

MAXIMUM SPEED OF THE MANDREL FEED AXIS | 90m/min | 90m/min | 120m/min | 120m/min |

MAXIMUM SPEED OF THE LASER HEAD AXIS | 90m/min | 90m/min | 90m/min | 90m/min |

MAXIMUM SPEED OF THE MANDREL FEED AXIS ACCELERATED | 1G | 1G | 1.2 G | 1.2 G |

MAXIMUM ACCELERATED SPEED OF THE LASER HEAD AXIS | 1G | 1G | 1.2 G | 1.2 G |

VITESSE MAXIMALE DE L'AXE Z | 60m/min | 60m/min | 60m/min | 60m/min |

| Mild steel | Stainless steel | Aluminum | Brass | ||

|---|---|---|---|---|---|

Resonator power 1500W | Production (drilling): Rough cut Maximum thickness | 12 mm | 6 mm | 5 mm | 4 mm |

Resonator power 3000W | Production (drilling): Rough cut Maximum thickness | 16 mm | 8 mm | 8 mm | 6 mm |