WOOL JET is a high-pressure waterjet cutting machine designed to process soft materials such as technical foams (PU, EPDM, neoprene, PE, EVA), natural or synthetic rubbers, flexible and rigid PVC, as well as soft plastics, with thicknesses ranging from 0.2 to 120 mm depending on their density and hardness. Cold cutting preserves the integrity of materials and ensures repeatability, dimensional consistency, and quality, including for the most complex shapes.

This technology applies to many industrial sectors, prototypes and small series without tooling, but also large volumes with repetitive cuts:

It enables, for example, the production of polyurethane foam gaskets for:

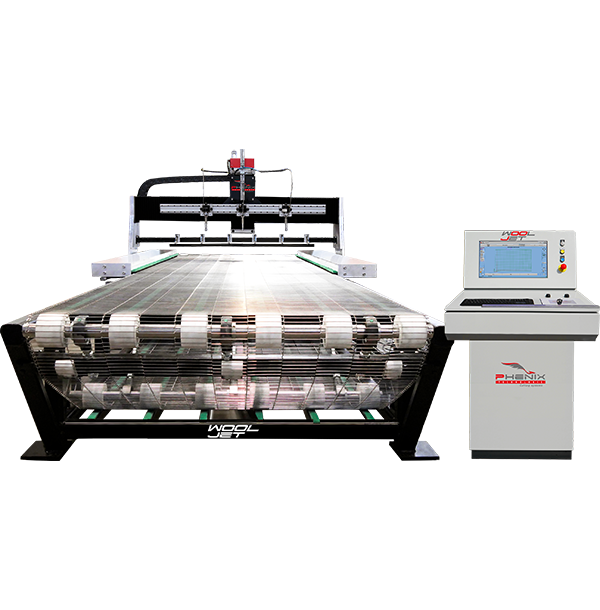

Designed for all production needs, the WOOL JET can be configured:

with a single cutting head on a compact 1.3M x 4M format for small series and craft applications

with multi-head cutting, three jets on large formats up to 3 x 8 m of usable cutting surface in order to ensure intensive production on several strips, with high throughput and maximum productivity.

The articulated stainless-steel mesh conveyor, driven by motorized axes, ensures the automatic unwinding of material rolls, translation under the cutting bridge, and evacuation of finished parts, thus guaranteeing a smooth and automatic workflow.

Operated by the Oxyjet interface, the WOOL JET combines productivity, reliability, and low maintenance with great versatility and precision. Unlike simple samples, it produces real finished parts, ready to use, compliant with drawings and strict tolerances, allowing a direct transition from design to production.

The WOOLJET pure waterjet cutting center consists of a welded steel frame with rectified mechanical surfaces.

The massive bridge supporting the high-performance cutting head(s) features dual drive motors. WOOLJET is equipped with the OXYJET multi-process CNC developed by PHENIX TECHNOLOGIE.

The X, Y and Z axes feature:

The advanced design of WOOLJET and the use of premium components allow:

Minimizing machine wear caused by the harsh waterjet cutting environment

Ensuring long-lasting precision

Achieving a low operating cost

Accuracy: +/- 0.1 mm

Repeatability: +/- 0.05 mm

Usable cutting area X, Y, Z: from 1,300 mm x 4000 mm to 3000 mm x 8000 mm

Materials to be cut with pure waterjet: Metals, Rubbers, Plastics, Composites, Foams, Wood